Every two years, the NRK Rethink Awards gives a platform to entrepreneurs whose products and initiatives contribute to sustainability and the circular economy. The awards, organized by the Dutch Rubber & Plastic Industry Association 9 (NRK) Nederlandse Rubber- en Kunststofindustrie, celebrates innovation and sustainability. This remarkable event will be presented on Wednesday, September 17 during the Plastics Fair at the Brabanthallen ‘s-Hertogenbosch. The OPACKGROUP is presented by nominations in three categories for these awards.

CATEGORY – RECYCLING

Recyclable gas barrier packaging for chilled French fries – Fardem Packaging

Fardem circular fries packaging

Fresh French fries are so sharp that they could easily pierce through the packaging film. For this reason, nylon (PA) and polypropylene (PP) have always been used for French fry packaging. Fardem Packaging B.V. (OPACKGROUP)’s new multi-layer recyclable film solves this problem without the addition of these polymers. The result is fully recyclable packaging with the right puncture resistance. Because only one polyolefin is used, customers can maximize the discount from Verpact‘s rate differentiation. With this film, the company is anticipating the upcoming EU Packaging & Packaging Waste Regulation (#PPWR), in which recyclability is an important element.

CATEGORY RE-USE & RE-DUCE

TopEmboss® Ultra – Plasthill

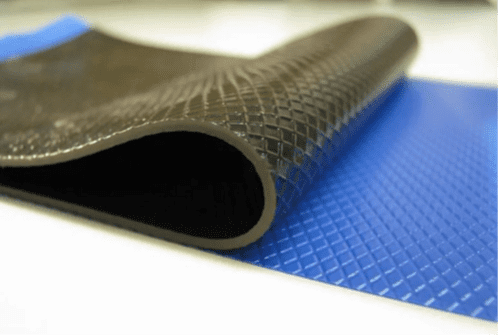

closeup Plasthill MDO TopEmboss Ultra film

Plasthill developed this embossed release film for the prepreg and rubber industry. When processing prepreg and rubber, the sticky semi-finished products are rolled up and, because they must remain separate, a release film is applied between the layers. Stiffness, flatness, tear resistance, and creasing play an important role here. To achieve these properties, films between 60 and 100 Mu are often used. By using a length oriented LDPE film instead of a normal LDPE film and embossing it, a 20 to 40% reduction in thickness and weight can be achieved, depending on the original thickness. Together with our colleagues from OPACKGROUP Technology Centre (OTC) and Plasthill, we designed and patented this innovation. Thanks to the Machine Direction Orientation (MDO) process, the film is not only thinner than regular embossed films, but even better, TopEmboss Ultra improves processability and enhances technical properties, making it more efficient and reliable in the production process. By combining sustainability, functionality, and efficiency, TopEmboss Ultra stands out as the ideal solution for the rubber and composites industry. Due to the high demands on product and process reliability, no recycled or biobased raw materials are used in release films. Material reduction is therefore the most effective sustainability strategy.

CATEGORY SUSTAINABLE RAW MATERIALS

Sustainable French fry packaging – Oerlemans Plastics

Product presentation of the LambWeston fries biobased packaging

Lamb Weston has launched this European retail packaging made from used vegetable frying oil for its frozen potato products. The packaging was developed by @Oerlemans Plastics in collaboration with chemical company @SABIC and frozen fries producer Lamb Weston. The used frying oil is collected as organic waste from Lamb Weston’s production and processed into biodiesel and bionaphtha in a biorefinery. The bionaphtha is cracked by SABIC together with conventional raw materials. During this process, contaminants are separated and only clean monomers remain, which are then processed into polymers for the production of granulate. Oerlemans Plastics uses the ISCC PLUS-certified biocircular polymers to make a multi-layer flexible PE film for Lamb Weston’s retail packaging. In addition, the new packaging is also 20% thinner, resulting in a total reduction of 30% in CO2 emissions compared to previous packaging

These three nominations are realized by our following team: Marcel Veltenaar, Rob Verpaalen, Nick Kimman, Cas Veenhoven, Rogier Hertogh, Laura Hanegraaf, Rob van der Bruggen, Sander Kool and all other colleagues from the OPACKGROUP and OPACKGROUP Technology Centre who contributed to these innovations. Furthermore we would like to thank our strategic suppliers and our customers for their continued partnership. We are confident that these nominations will be successful at the upcoming Rethink Awards!

OPACKGROUP “the sustainable innovator”